Plastic injection thin-wall box mold huangyan mould supplier

栏目:MOULD BLOG 发布时间:2025-01-23

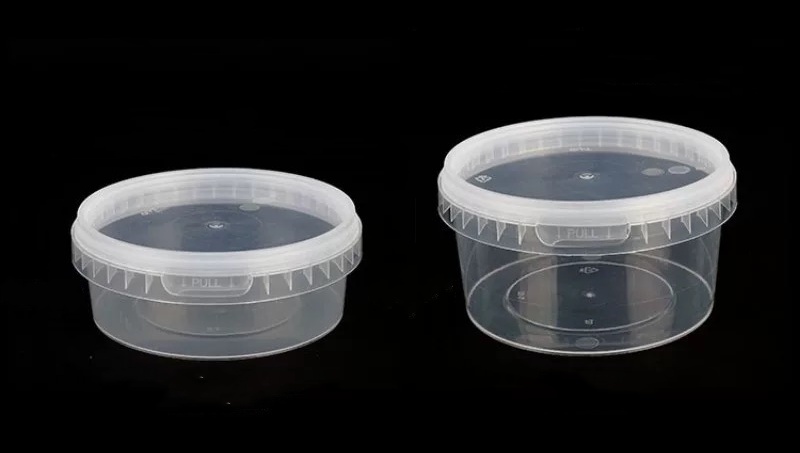

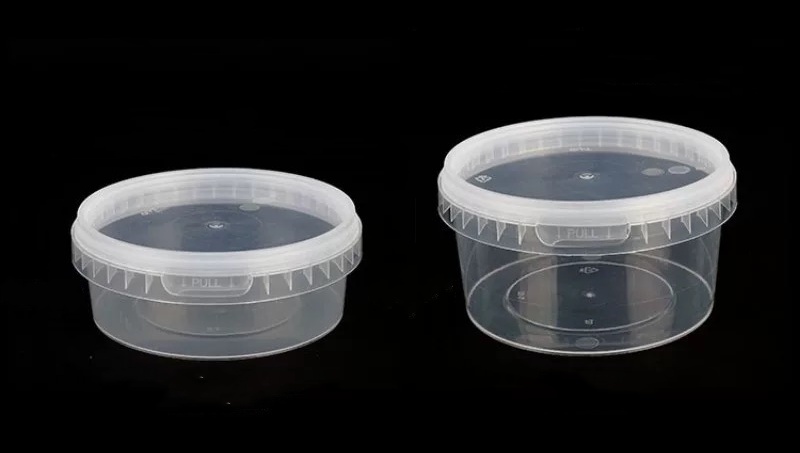

In the fast-paced modern life, the packing box has long become an intimate partner in our daily diet. Whether it's takeaway food or restaurant leftovers, thin-walled boxes are everywhere. However, few people will pay attention to the fact that behind these lightweight and practical packaging boxes, thin-walled packaging box mold are silently playing a key role.

1. The thin-wall box mold operating principle

Thin-wall box mold usually use injection molding, it is need to put the mold on the injection machine, and then put the plastic material into machine barrel, through thread and injection, the thin-wall box will come out. But due to the thin-wall box thickness is less than 0.5mm, so that the thickness in the box is very important. Otherwise it is easy to have flash or air trap. So that every detail needs to be carefully designed to ensure that the packaging box produced is precise in size and uniform in wall thickness. This technology can not only achieve efficient mass production, but also ensure the stability of product quality.

2. The thin-wall box mold design

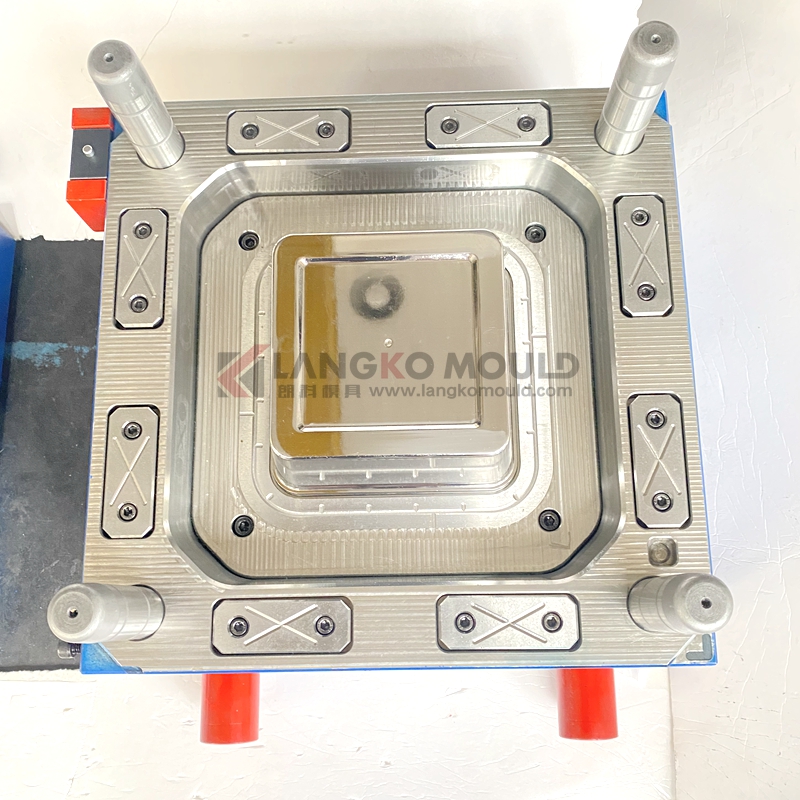

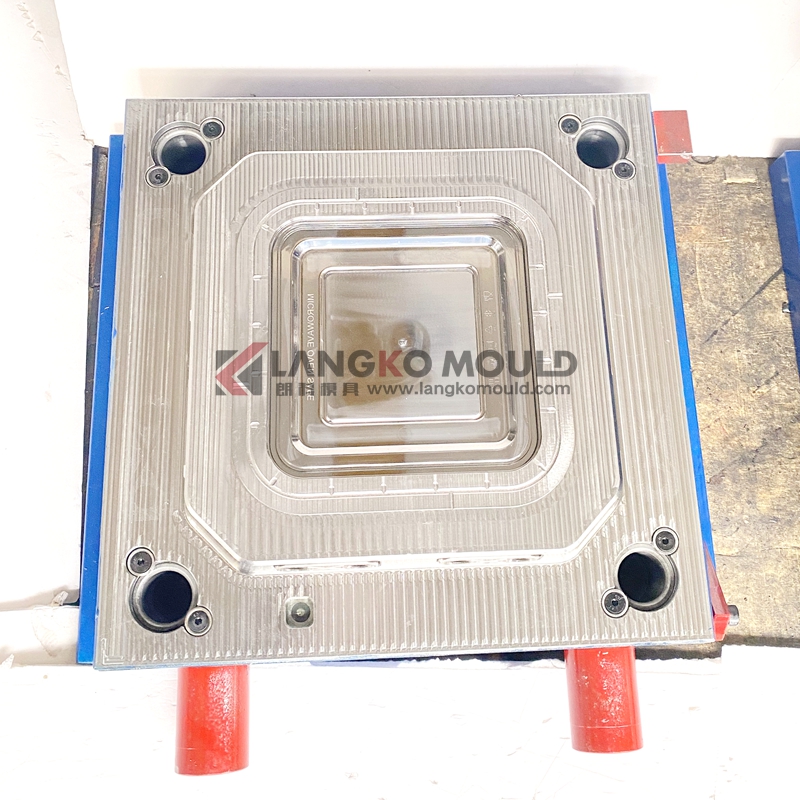

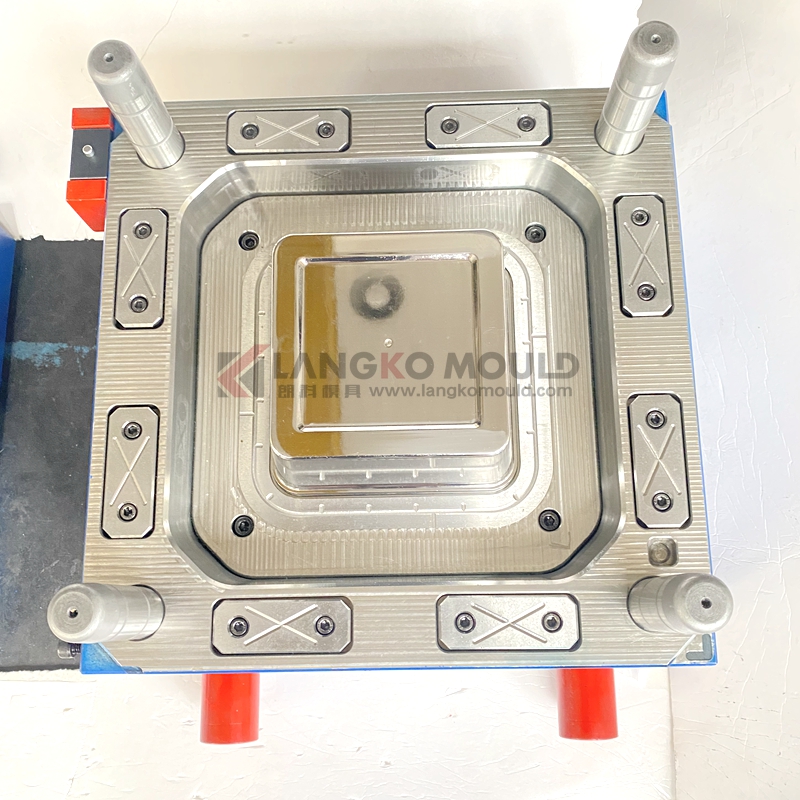

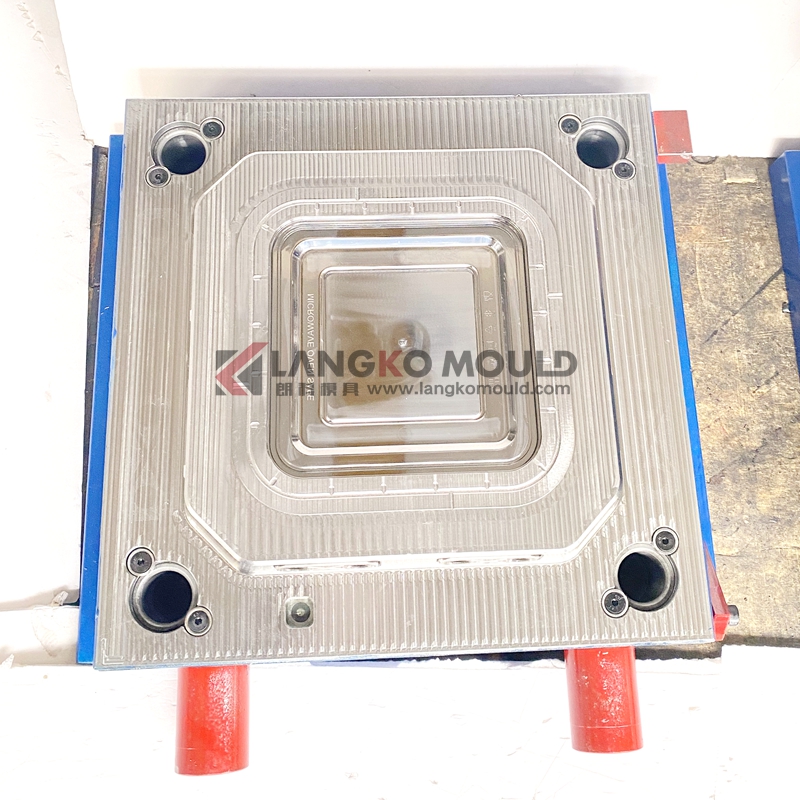

Cavity and core: it is will have different design for the cavity and core, like make self-lock, insert or whole. And for the different lock way, we will make the different design on the cavity.

Cooling line: As the thin-wall box mold is normally run in high speed injection machine, then the cooling line layout is very important, if it is not good, then the product is easy to deformation.

Demold way: The common demoulding methods are ejector pins demoulding,stripper plate demoulding, air ejector etc. Each method has its applicable scene, which needs to be selected according to the specific situation of the mold.

3. The mold steel choose

The thinwall box mold steel quality will effect the mold life and product quality. We recommend to use S136 steel as mold steel. Due to S136 steel has good strength and wear resistance. It is could bear high pressure and high temperature, to make sure the mold will not deformation during long long use.

4. The importance of molds in the industry

Due to now thin-walled packing boxes are in great demand. And the boxes are made by the thin-wall box mold , the quality and performance of the mold directly determine the quality, production efficiency and cost of the packaging box. A high-quality mold can produce millions of packaging boxes, saving a lot of production costs for enterprises. At the same time, with the continuous improvement of environmental protection requirements, higher requirements are put forward for the lightweight, high strength and degradability of thin-walled packaging boxes, which also encourages mold manufacturers to continue to innovate and develop more advanced mold technology to meet the needs of the market.

If you have any interests in the thin-wall box mold, pls contact us.

Wechat/whatsapp:+86-18158636422

1. The thin-wall box mold operating principle

Thin-wall box mold usually use injection molding, it is need to put the mold on the injection machine, and then put the plastic material into machine barrel, through thread and injection, the thin-wall box will come out. But due to the thin-wall box thickness is less than 0.5mm, so that the thickness in the box is very important. Otherwise it is easy to have flash or air trap. So that every detail needs to be carefully designed to ensure that the packaging box produced is precise in size and uniform in wall thickness. This technology can not only achieve efficient mass production, but also ensure the stability of product quality.

2. The thin-wall box mold design

Cavity and core: it is will have different design for the cavity and core, like make self-lock, insert or whole. And for the different lock way, we will make the different design on the cavity.

Cooling line: As the thin-wall box mold is normally run in high speed injection machine, then the cooling line layout is very important, if it is not good, then the product is easy to deformation.

Demold way: The common demoulding methods are ejector pins demoulding,stripper plate demoulding, air ejector etc. Each method has its applicable scene, which needs to be selected according to the specific situation of the mold.

3. The mold steel choose

The thinwall box mold steel quality will effect the mold life and product quality. We recommend to use S136 steel as mold steel. Due to S136 steel has good strength and wear resistance. It is could bear high pressure and high temperature, to make sure the mold will not deformation during long long use.

4. The importance of molds in the industry

Due to now thin-walled packing boxes are in great demand. And the boxes are made by the thin-wall box mold , the quality and performance of the mold directly determine the quality, production efficiency and cost of the packaging box. A high-quality mold can produce millions of packaging boxes, saving a lot of production costs for enterprises. At the same time, with the continuous improvement of environmental protection requirements, higher requirements are put forward for the lightweight, high strength and degradability of thin-walled packaging boxes, which also encourages mold manufacturers to continue to innovate and develop more advanced mold technology to meet the needs of the market.

If you have any interests in the thin-wall box mold, pls contact us.

Wechat/whatsapp:+86-18158636422

86-0576-81122860

86-0576-81122860